The Science of Pure® Technology Working For You

TECHNOLOGY WORKING FOR YOU

PuroGen pedigree

PuroGen’s story began in 1997, when our founder launched a pioneering biomedical company in Central Florida. Early innovations focused on the procurement, manufacturing, and sterilization of cadaveric allograft (human) tissue—experience that formed the foundation for PuroGen’s programmable and validatable Vaporized Hydrogen Peroxide (VHP) sterilization with Reactive Oxygen technologies.

Over time, we expanded our capabilities to include pathogen control for medical devices, pharmaceuticals, biotechnology, and in addition to purification we now offer terpene infusion for agriculture, including sensitive cannabis and hemp materials.

Game-Changing Technology: TheBOX

At PuroGen Laboratories, we don’t just build sterilization systems — we engineer game-changing solutions. Our flagship product, TheBOX, redefines the industry by combining patented sterilization, rehydration, and infusion capabilities into a single, breakthrough system for life sciences, healthcare, and cannabis. This technology isn’t merely innovative—it’s transformative, setting new standards in quality, safety, and efficiency.

Commitment to Sustainability

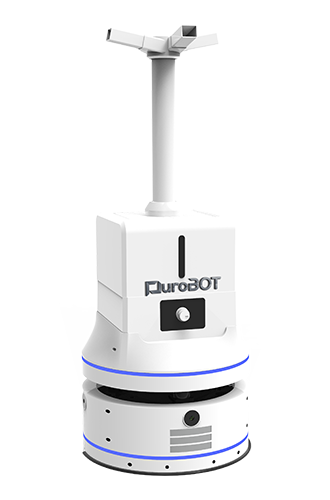

A key differentiator is our green technology, which delivers zero impact on all biologics—including plant materials—while leaving no carbon footprint. Our air purification and robotic sterilization solutions are used worldwide, making PuroGen a trusted partner for delicate biofilm sterilization, large-scale pathogen control, and infusion of plant materials in both commercial and public sectors.

AI-Driven Future

Looking ahead, we are integrating full AI into our product line for real-time feedback and program optimization. By collecting blind data from our machines, our systems will continuously learn and self-improve, elevating sterilization effectiveness and boosting overall productivity for clients around the globe.

Collaborative Partnerships

Through a collaborative approach, we partner closely with life science companies, labs, agriculture producers, and cannabis/hemp clients to develop customized solutions. From precise biofilm sterilization to large-scale pathogen control, our programmable VHP platforms deliver the validatable performance you need to stay ahead in a competitive market.

APPLICATIONS

TRANSPLANTS

Our non-irradiated solution provides a terminally sterilized allograft (human) tissue while preserving all of the natural biological properties

CANNABIS

Does not impact the original properties of cannabis and hemp such as THC, CBD or Terpenes

MEDICAL DEVICE

In-house supply sterilization process with 20 minute cycle times and powerful SAL 10^-6 reduction kill capability

GENETICS

Safely sterilize without affecting the integrity of genetic makeup for biologic material